Precision Vinyl Record Cutting System

Developed a time-frequency error analysis framework for precision control of a vinyl record cutting system

The Problem

For the American Society of Precision Engineers Student Challenge, we built a precision positioning system to cut playable vinyl records. Traditional positional error metrics are meaningless for audio applications.

A constant 10µm offset looks catastrophic to standard tracking metrics, but the audio is perfect. Meanwhile, a 1µm vibration at the wrong frequency creates audible distortion but looks fine in position space. We needed to analyze the system in the frequency domain where audio actually lives.

Time-Frequency Analysis Framework

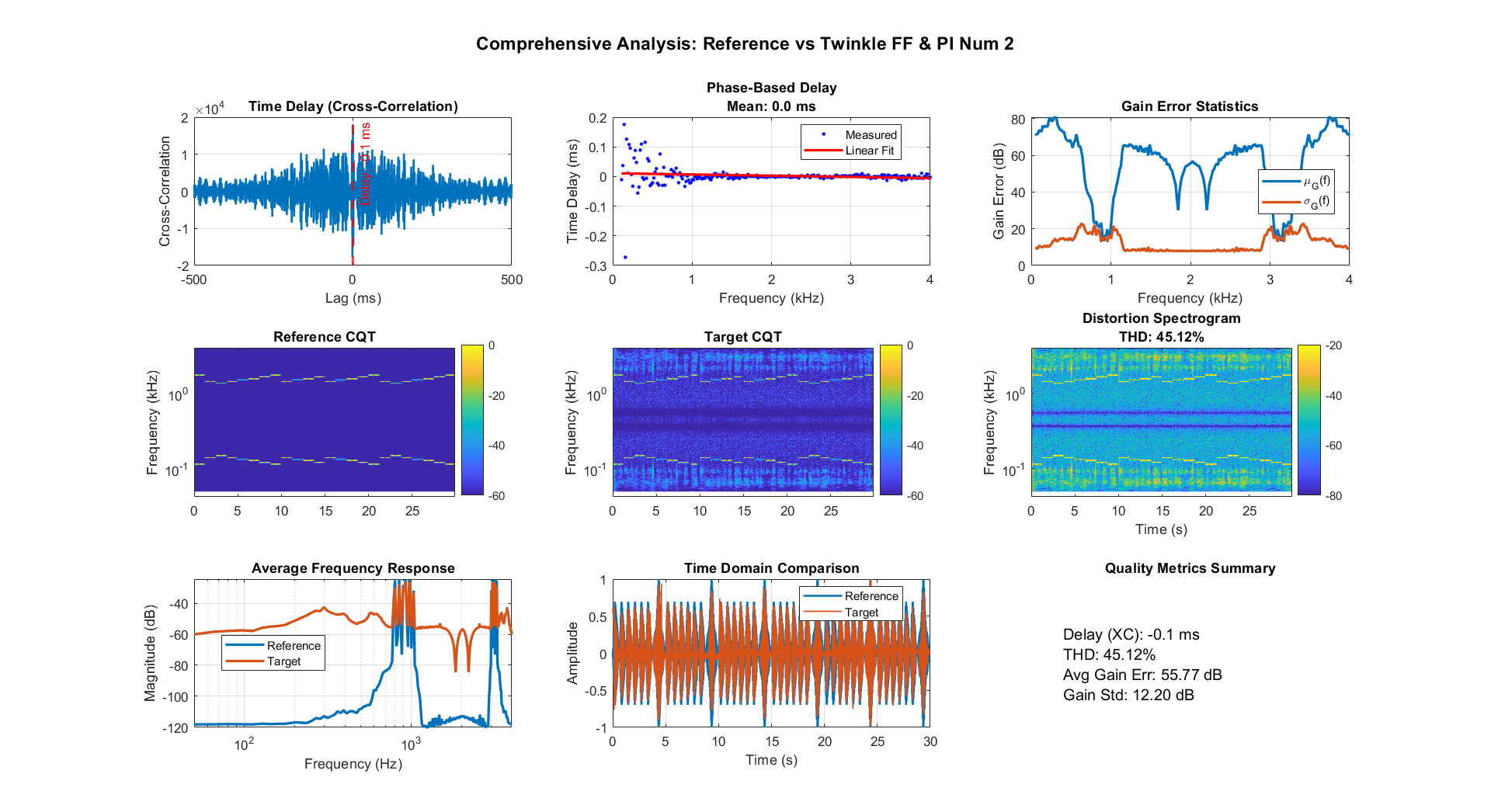

I developed a three-metric framework using the Constant-Q Gabor Transform to characterize system performance. The CQT provides optimal time-frequency localization while matching the logarithmic structure of human hearing and musical scales.

The Three Metrics

Gain Error: Quantifies amplitude reproduction accuracy at each frequency over time on a logarithmic scale. Mean and variance distinguish systematic equalization errors from time-varying compression or instability.

Phase Distortion: For linear systems, pure delay produces constant group delay across frequency. I compute instantaneous phase differences, fit linear regression, and check for non-zero slope or high residuals indicating frequency-dependent phase distortion.

Total Harmonic Distortion: Measures energy appearing at frequencies not in the input. After power normalization, THD reveals nonlinearities from hysteresis, clipping, and thermal effects.

Why This Matters

Standard Fourier analysis assumes stationary signals, which breaks down for music. The CQT uses variable window lengths (longer at low frequencies, shorter at high frequencies) to provide the right resolution where it's needed.

Control Implementation

The diagnostic framework identified a resonance at C3 (130.8 Hz) where the controller struggled. I implemented two strategies:

- Feedforward control to improve amplitude matching and reduce phase-based delay

- Resonant noise cancellation by commanding a sine wave at the natural frequency

For song selection, we avoided the resonance entirely by choosing material without C3 content.

Results

-16ms → -0.2ms

Time delay reduction

±9.27dB → ±6.7dB

Gain variance improvement

C3 at 130.8 Hz

Resonance identified and mitigated

Met target specifications of ≤2ms delay and ±2dB gain error. Successfully cut a playable vinyl record. THD remained above target due to mechanical limitations including hysteresis and thermal deflection at the scribe contact point.

The framework also enables rapid mechanical diagnosis. Hysteresis produces odd-order harmonics, thermal drift creates time-varying gain, and mechanical deflection shows resonant peaks at natural frequencies.

Full Technical Report

Complete mathematical derivations and diagnostic procedures: