Simulation for developing novel volumetric 3D printing

Paper: A Physics-based Machine Learning Algorithm for Accurate Vat Photopolymerization

Patent: Triggered Luminescence and Machine Learning for Optimized Resin Printing

Project

Gradient Descent Optimization

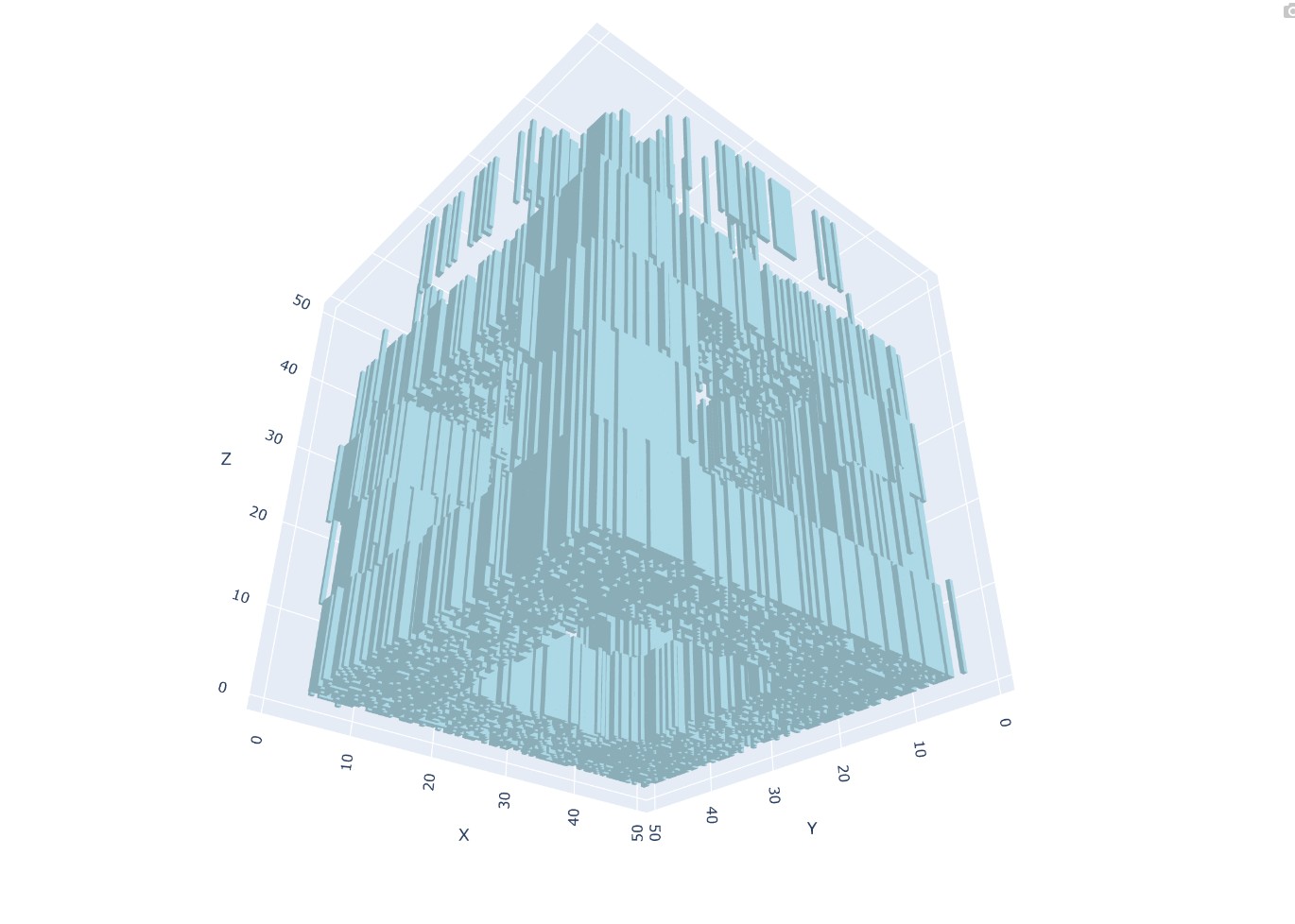

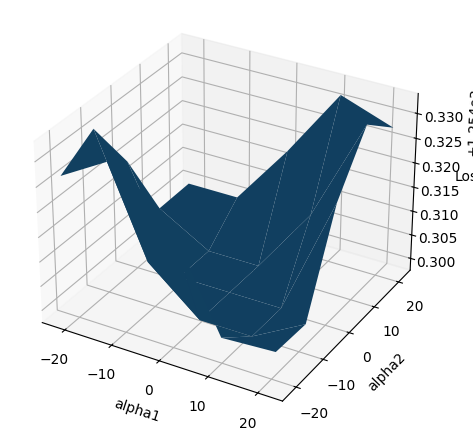

I worked on the inverse problem of holographic fabrication: determining a phase-only hologram that generates a prescribed three-dimensional light intensity distribution. Because the governing wave-propagation PDEs are forward-only, the inverse mapping is highly nonconvex and analytically intractable.

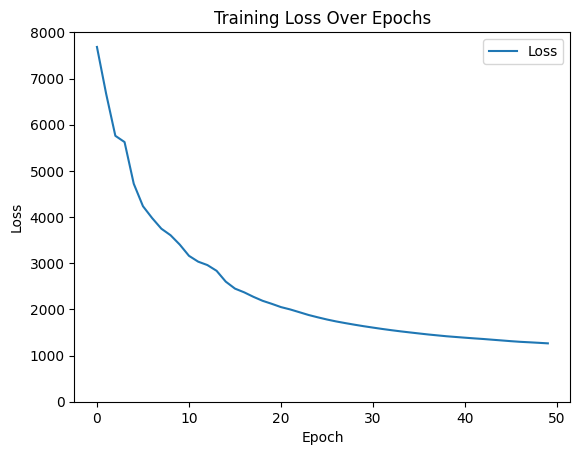

I addressed this by building a gradient-based optimization pipeline inspired by modern machine learning. Using automatic differentiation, I optimized hologram parameters directly through the physical propagation model. I applied techniques such as loss-landscape visualization, hyperparameter tuning, and stability analysis to ensure reliable convergence. The resulting system consistently produced physically realizable holograms that closely matched target geometries, demonstrating a practical computational approach to inverse holographic design.

Orders of magnitude faster

Convergence speed compared to earlier models

95% Accuracy

Match between target and achieved geometry

0.5um Resolution

Improved feature resolution in printed objects

Images