Kushaal Singh

I am a Mechanical Engineering, Mathematics, and Plan II Honors student at UT Austin. I'm very interested in computational methods and the applications of pure math in engineering, specifically with how they apply to microelectronics and the semiconductor industry.

Experience

Nanoscale Design & Manufacturing Laboratory

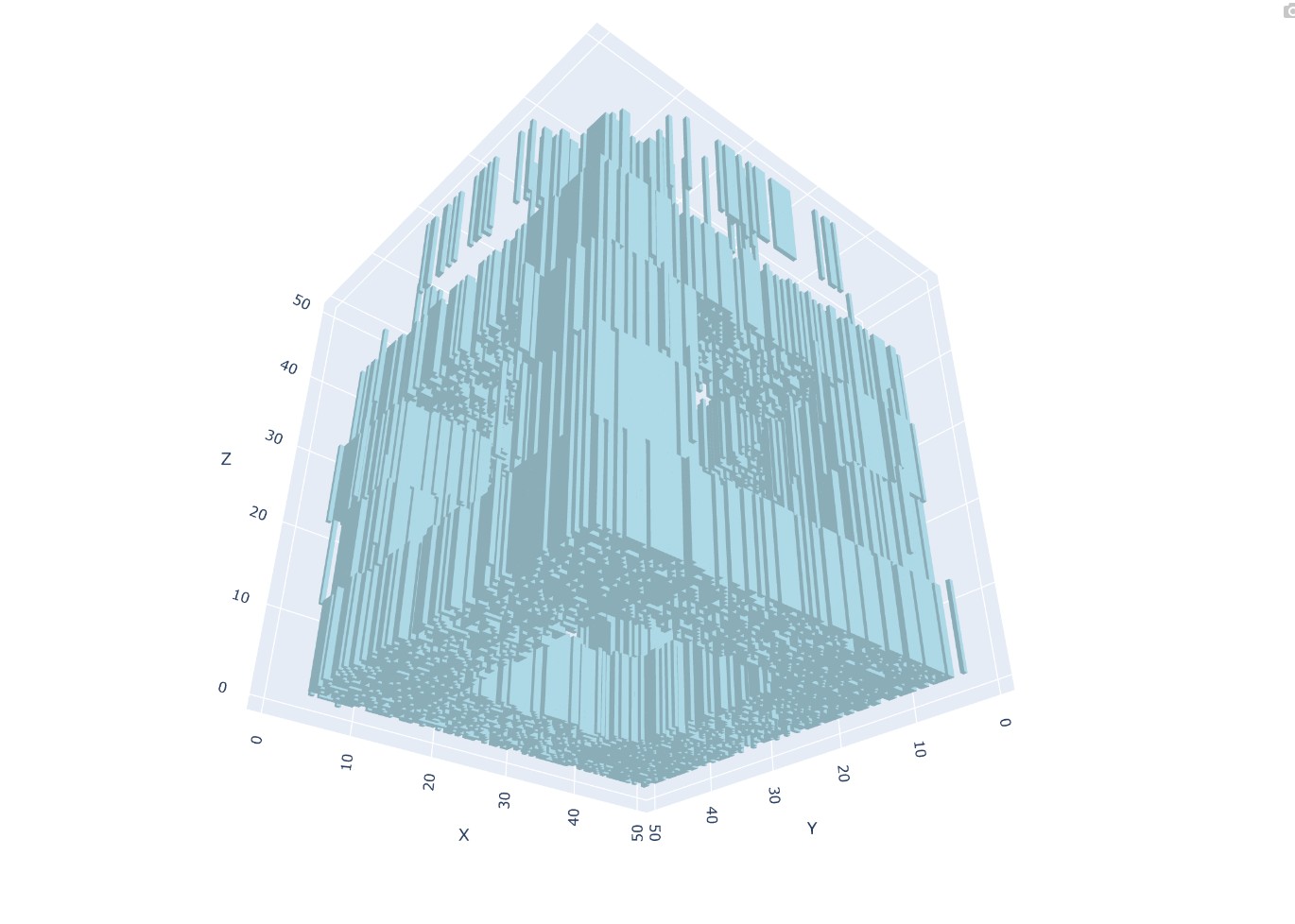

Over the summer, I rejoined this lab, which I had previously been a part of. I now worked more on simulation and computational methods, using holograms in a vat of resin to cure a 3d object volumetrically. I use gradient descent to approximate solutions to this highly intractable problem and have greatly improved my programming ability with this experience. We also use a diffusion model of dissolved oxygen to inhibit the photopolymerization process as we need.

Longhorn Racing Electric

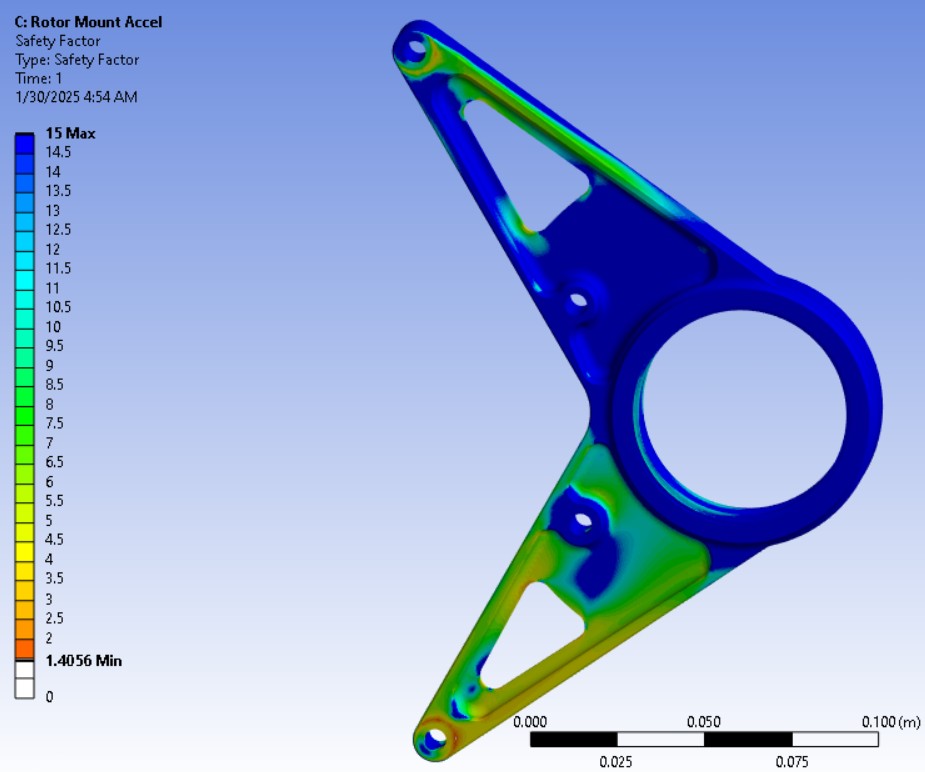

I joined LHR in 2023 and in 2024 became the Drivetrain lead. I've grown a lot in terms of skill of mechanical design and analysis, but also in terms of general knowledge. I was initially drawn to the drivetrain team because of the attitude towards innovation and the fact that it was a team that was growing and still had much to learn. My freshman year (2023-2024) I spent the design season working on a sprocket, where I boasted 20% weight savings to the previous year.

I spent the manufacturing season of that year helping as much as I could, manufacturing for the Aerodynamics and Dynamics teams in addition to my own parts.

I then found my time occupied overseeing the drivetrain subsystem, working with integrating my assemblies into the rest of the car, while still having a lot of part level design.

Under my leadership, we pursued a project where we tried to innovate with Carbon Fiber halfshafts, which yield high weight savings, but are very complicated to validate. I've had to learn a lot about analysis for anisotropic materials and I've made a matlab code to easily calculate stresses and the safety factor for various tubes under our loading conditions.

Despite spending so much time around a racecar, I wouldn't call myself a car person, but I love this group for the high amount of personal responsibility and ownership and, of course, the comaraderie.

The drivetrain team was a total of 5 engineers, all of whom I managed.

Physics Directed Reading Program

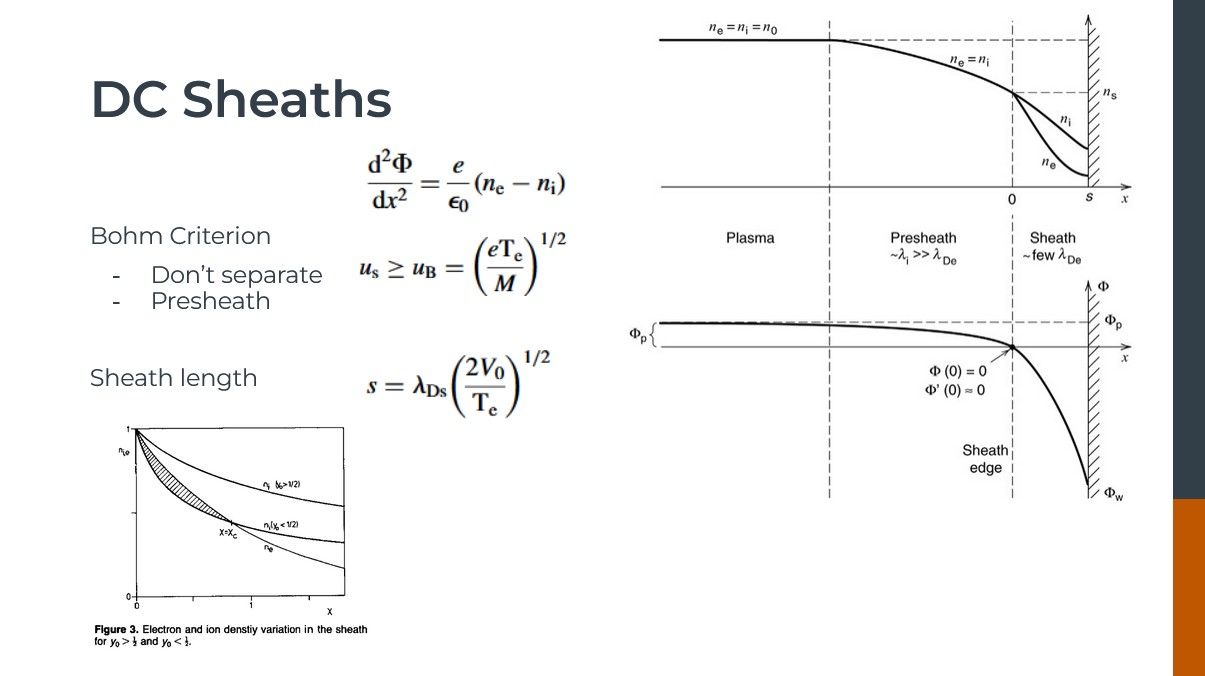

In the Data Analytics for Semiconductor Manufacturing course I was in, my professor mentioned Coulomb Crystals being generated by the semiconductor manufacturing process. I was really interested in this, so I decided to join the Physics Department's reading program, where I sat with a graduate student and we read through a textbook, front to back, together.

I was able to learn a lot about plasma processes and we steered our reading to be mostly about the applicable parts to semiconductors. The physics was very interesting to me and is something I hope I can continue to keep learning about. Because of this program, I've decided to take Electrodynamics with the physics department, with the hope that I might take more plasma classes in the future.

Paradigm Robotics

I joined Paradigm Robotics in 2024 after hearing about the interesting challenges of the drivetrain from a friend who was already working with them. This is a robotics startup trying to create a robot to aid firefighters in search and rescue by entering burning buildings. It is surprising how many things, which might normally be taken for granted, break down at such high temperatures (~600 degrees C). You can't use standard lubricant, loctite, and you have to analyze the thermal expansion of everything. I joined after a majority of the design was concluding as we moved into the manufacturing phase, so much of my work was done in that area. It is a fascinating project and I'm happy to be a part of it.

Nanoscale Design & Manufacturing Laboratory

As part of this lab, I helped study the effects of stress in roll-to-roll manufacturing, where a role of a polymer is imprinted with nano-size electronics. The hope with this research is that it might overcome the size and flexibility limitations of silicon wafers, but it has a shortcoming in it's inconsistency. As such, we sought to study the stress and strain using the photoelastic effect, where the retardation (distance between peaks of light rays) was measured as the stress was varied in magnitude and direction. My main contribution was creating the testing set up, in addition to collecting the data. I designed and manufactured the jigs, which ended up actually being the first time I ever used a manual mill.

I applied to and ended up attending UT because of, in part, the research that goes on here. There are so many fascinating boundaries being pushed and I am glad I was able to be part of one such lab.